| Features | Benefits |

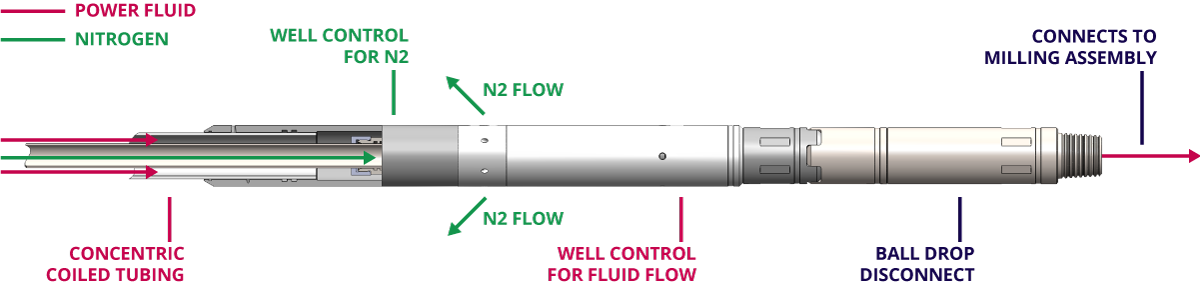

| Separate nitrogen and power fluid flow paths | Adjust nitrogen and power fluid independently |

| Fluid only to the mud motor | Extend mud motor life, optimal torque output and consistent port and plug milling time |

| Improve cuttings and wellbore material circulation | Reduce operational risk |

| Reduce nitrogen product usage | Decrease operation costs |

| Check values and redundant disconnects in the BHA | Prevent inflow and maintain well control |

| Specifications | |||||||

| CCMS OD | Jar and Motor OD | Maximum Temperature | CCT OD | ||||

| mm | in | mm | in | ºC | ºF | mm | in |

| 79.4 | 3.125 | 73.0 | 2.875 | 150 | 302 | 60.3 | 2.375 |

| 66.7 | 2625 | ||||||

| 73.0 | 2.875 | ||||||